Businesses which fall into the trap of putting too much focus on manufacturing and inventory costs are being held back from their full potential as they fail to acknowledge the inefficiencies arising through weak links in the supply chain.

The increase of smaller SKU orders placed online around the clock in a widening global marketplace is forcing warehouses to evaluate their supply chain and implement strategies to optimize and automate in every way they can to cut costs in their supply chain.

Efficiency and speed of delivery, in your supply chain, is now taking precedence as the new benchmark for excellent customer service. Businesses are starting to realize that differentiating themselves in the marketplace, minimizing processing and risk as well as decreasing cost, often comes down to improving the execution of their supply chain.

Therefore, a business must devote some of its resources to developing systems which maintain its competitiveness and provide opportunities for growth.

Improving the efficiency of the supply chain by pinpointing its weak spots, and then implementing plans to optimize it for greater responsiveness is one way in which a company can remain competitive in the fast-moving digital marketplace.

In this way, a business will be able to improve their functional capacity throughout the entire value stream.

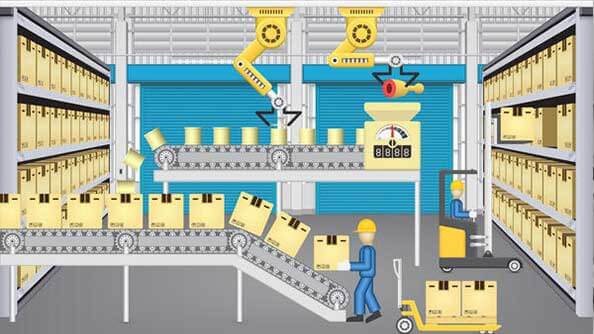

Technology has always had a fantastic ability to iron out deficiencies in business operations. Robots are an up and coming force in the push towards higher levels of automation in the supply chain, but the technology still has a while to go yet before it becomes affordable to the mainstream.

However, there are still plenty of options for increasing the efficiency and production capacity of your workforce, as well as technologies which can dramatically improve warehousing and storage capabilities.

Automation Strategies for a Digital Global Marketplace

How Conveyor Systems Improve Your Supply Chain

Conveyor systems are a belt arrangement which can transport items throughout the warehouse. A well-designed and efficient conveyor system will negate the need for employees to physically transfer goods from one section of the warehouse to another, saving time, increasing productivity, and by extension, improving responsiveness.

Advanced conveyor systems also allow for the possibility to transfer products or materials through the various stages of a process to reduce material handling and its associated costs.

Conveyor systems are not confined to transporting goods throughout a single floor, as it is possible to install systems which are capable of transferring materials to the different levels of a multi-story building.

Voice Picking and Pick to Light

Managers are acutely aware of the human impact error has on their business, from relatively minor mistakes like sending Sally the wrong size pair of shoes, to major ones such as thousands of products rolling off the production line which are the wrong color.

The days of a system operated entirely by human hands are long behind us, as order fulfillment technology has progressed by leaps and bounds during the last couple of decades. Voice picking systems and pick to light solutions have made great strides in reducing the possibility of human error during the order fulfillment process.

Voice Picking, as its name suggests, involves a human and computer working in tandem to increase efficiencies in warehouse order picking.

Headsets with microphones are supplied to the workers, who then receive automated audible instruction as to the location of the materials or products needed to complete the order.

Once the team member has picked the corresponding item, they then reply with a verbal confirmation, which signals the system to move on to the next item on the packing list.

Workers are no longer required to pick orders by continuously wasting time glancing at an invoice, and then looking up to find the relevant section; a process which is laborious, time-consuming, and prone to errors. Throughput is also increased as employees can always work with both hands free, and move with speed and efficiency from one storage location to the next.

A Pick to Light system is a system which uses illumination and barcodes instead of voice automation. Employees scan a supplied list of barcodes, the information is then transferred to the system, and a series of lights are illuminated around the warehouse to designate the locations of the required products or materials.

Many light systems also use lights which indicate the quantity of each item required to achieve order fulfillment, reducing even more instances where human error may occur.

How Storage and Space Utilization are Critical to Your Supply Chain

Storage is a critical component of supply management, and one of the most challenging, with managers continually having to prioritize stock levels according to market changes and consumer demand.

Expansive warehouses are not always the answer to managing stock, as storing large quantities of products always comes with an associated cost. Maintaining high quantities of stocks increases the risk of lost revenue, as demand for the product may dwindle before stock runs down. A warehouse is then storing products nobody wants and has less room available to replenish the more in-demand products.

Travel time between locations will also contribute to lowering the responsiveness and speed of order fulfillment. Fortunately, there are flexible storage solutions which optimize efficiency in both the vertical and horizontal space of the warehouse.

Vertical pick modules are high-density storage systems, such as Vertical Lift Modules, that are perfectly geared to processing orders with high-volume stock keeping units (SKUs).

Intelligent software systems are employed to rapidly transport the storage unit to the order picker, increasing accuracy while also speeding up order fulfillment. The same concept for automated high-speed order picking systems is also available through horizontal storage carousels that maximize the use of available space in the warehouse.

Optimizing the supply chain, and increasing efficiency are critical to the success of modern businesses operating in a world where a product is but a mouse click away at any time of the day or night. Companies which are proactive in using every technological advantage to meet customer demands will improve efficiency, reduce waste, and increase profits.

See if Aero Fulfillment Services is the right fit for you by taking this 1-minute survey.