Since their inception, the goal of fulfillment centers and third-party logistics (3PL) providers has been to get goods from warehouse to customer in the fastest, most efficient way possible, without sacrificing quality of service. In this age of ecommerce, the task is even more challenging. Not only has this method of purchasing exploded, but purchasers are demanding and expecting quick, reliable delivery. Additionally, fulfillment centers have been faced with labor shortages and demands for higher wages.

Considering this, the logistics industry is relying more and more on robots to help them keep their clients happy. The key to effectively employing these machines is in understanding where their utilization will generate the most efficiency.

Ideal Functions for Robotics

In the warehouse, many tasks can be delegated to machines, freeing up humans to do other things that require more technical expertise. Inventory tasks are ideal for robots. These robots come in both the stationary and mobile variety.

Stationary robots use articulated arms to load heavy goods onto pallets, pick from bins, package, sort, and place items on conveyor belts. They can also be programmed to order and route.

Mobile robots can complete automatic loading and unloading of trucks, taking the items to storage, and stacking where needed. They can transport heavy loads, including full pallets and bins. They can bring picked goods to the packaging area.

Vision systems, sensors, lasers, and advanced machine-learning software make robots the perfect companion for humans. They save humans from performing menial, repetitive, and sometimes unsafe functions that often result in ergonomic injuries. They also save humans from countless steps as they effortlessly travel across the warehouse. Not to be overlooked, robots can clean and provide surveillance.

Finding the Sweet Spot Between Robotics vs. Human Labor

Purchasing a robotic system can be costly. It is assumed that robots will generate cost savings and gains in productivity, but before taking the plunge, a company will need to be aware of its return on investment (ROI).

ROI = Net Gain / Cost

Several factors need to be included in an ROI calculation. On the investment side of the equation, the full cost of the system must be considered (such as accessories, transportation, installation, integration, and maintenance). On the return side of the equation, considerations include run-time of the machines, and any savings from less waste, less rework, and better product consistency. Although there will be labor savings, more skilled workers will be required to operate the robots.

Roberto Michel, writing in Logistics Magazine, cautions that as companies look to expand their reliance on robots, they need to be mindful of the integration process and costs. This is particularly important if robots from several vendors are being employed. These myriad machines need to work in harmony with each other and their human counterparts. The software needs to be able to communicate with the current warehouse management system (WMS). To address this need, companies have developed niche software platforms to orchestrate heterogenous fleets of robots and other types of automation, preventing conflicts and congestion between machines.

Several vendors offer calculators that will help you estimate the ROI. These calculators use assumptions around labor rates, training and programming costs, and other variables.

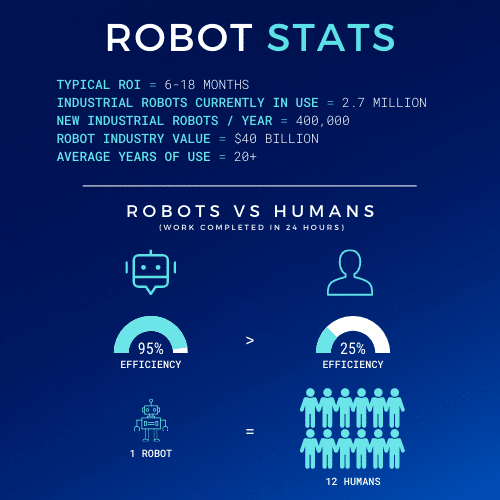

One such vendor, RobotWorx, provides some ROI estimates. They state that the typical ROI for a robotic system is 6-18 months. Robots run at 95% efficiency, while a human works at 20-25% (due to required breaks, fatigue, days off, etc.) One robotic system can do the work of 12 humans over the course of a 24-hour day. Once the ROI of a robot is realized, the savings really start to accrue. A typical machine may remain functional for 20 years or more.

Some vendors are offering robotics as a service (RaaS). This allows companies to test and learn the new technology before investing substantial amounts of capital. It also allows them to gradually move into this new era of warehouse management.

The Future for Robotics in the 3PL Industry

The use of automation in the logistics industry is expected to continue to grow. It is anticipated that the machines will become even more sophisticated. Words about robotics heard at a recent trade conference included agile, flexible, modular, scalable, green, fast, efficient, sustainable, and intelligent.

The transportation component of the supply chain is about to get very interesting. Automated trucks and ships are being tested for their ability to streamline moving products from factories to warehouses and distribution centers. These vehicles employ cameras, lasers, and GPS systems to safely navigate. Although they do employ a safety driver right now, eventually they will move autonomously, steaming ahead 24/7, utilizing the quickest route.

For end deliveries, drones and self-driving robots are also being tested. Sensors, computer vision, and GPS systems enable them to safely maneuver in urban environments. Benefits of these smart machines include providing significant cost savings, being eco-friendly, and improving safety.

Using robotics in the 3PL industry is a win-win. Companies see increased cost savings, better efficiencies, and improved safety. Customers see streamlined and faster service. Partnering with a 3PL that has embraced this new technology will ensure you are poised for future success.

See if Aero Fulfillment Services is the right fit for you by taking this 1-minute survey.